Charlie Browning has had a profound influence on the development of advanced composite materials for aerospace applications.In 1966, he became member of the U. S. Air Force Materials Laboratory team that invented advanced composites.He performed groundbreaking research on the study of humidity effects on graphite/epoxy composites, showing the detrimental impact on material properties and, thus, a detrimental impact on design allowables for aircraft.Broadening beyond in house research later in his career, he served as a technical advisor to numerous Air Force System Program offices including the F-16, B-1, B-2, and F-22 to help them overcome issues in implementing composites on those aircraft.His advice helped the aerospace industry understand the strengths and limitations of composites for these applications, and helped them understand how to fabricate composite parts.

In 1983, Charlie took on management roles in the Air Force, advancing from Technical Area Manager to ultimately the Director of the Air Force Research Laboratory (AFRL) Materials and Manufacturing Directorate.Through his management career, Charlie shaped the composites investment strategy that enabled the Air Force to realize the benefits of advanced composites on the F-16, B-1, B-2, F-22, and F-35.His investments in composite processing took composites from a poorly understood art to a physics based

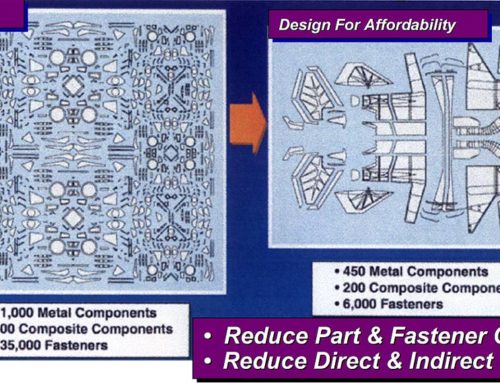

understanding of the impact of heat and mass transport.F-22 requirements mandated a highly toughened resin to meet impact damage requirements, so his investments in both thermoplastics and toughened epoxies have led to the materials in use today by the Air Force.Needs for lightweight turbine engine components led to his investments in fluorinated polyimides that are now in service on the Air Force’s F119 and F135 engines.Finally realizing that aircraft designers were becoming reluctant to use composites in a broad manner due the high costs shown by the F-22, he developed a joint program with the Navy called the Composites Affordability Initiative.This ground breaking work on bonded structures are scheduled to fly on high priority national security assets.In addition, through the confidence the aerospace industry gained on the use of composites for Air Force aircraft, they were able to apply composite to civil aircraft, from the general aviation community through commercial airliners like the Boeing 787.His leadership earned him the SAMPE Fellow award in 1996.

Currently, Charlie serves as the Torley Chair in Composite Materials and the Chair of the Chemical and Materials Engineering Department at the University of Dayton.In 2017, Charlie was awarded SAMPE’s Lubin Award for significant contributions in the field of material and process engineering.