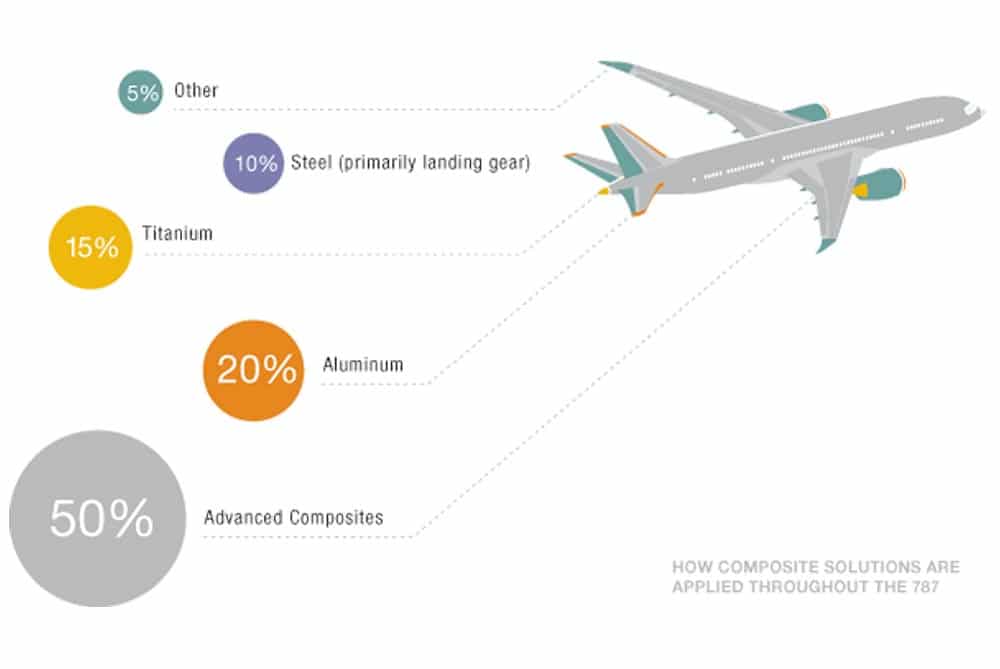

The journey for carbon fiber composites on commercial airplanes for Boeing has spanned decades. It started in 1984 when Boeing replaced the primary structure on a Boeing 737 Classic horizontal tail with the first carbon/epoxy primary structural piece as a study. From there, incremental insertion continued with the use of composites on the 777 empennage and floor sections. Then there was one final leap to use it on the 787 for primary structure throughout the airframe on the fuselage, wings, doors and many other components. Today, composite usage on the 787 equals about 50% of the aircraft by weight.

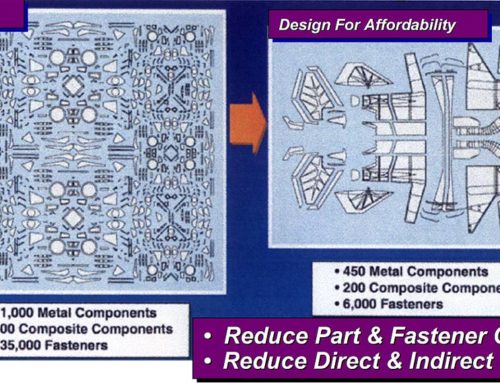

Use of CFRP on the 787 plays a significant role in the advantages the airplane has over other commercial models in the same class. The fabrication process of the singular composite barrel sections instead of multiple aluminum sheets leads to a significant weight decrease from reducing the fasteners used by 40,000 – 50,000. Carbon fiber composites also have a higher strength-to-weight ratio than metallic materials used in aircraft manufacturing and help make the airplane lighter overall by nearly 20%. In addition to lowering the airplane weight, moving to a composite primary structure promises to reduce both the scheduled and non-routine maintenance burden on the airlines.

The aircraft market continues to produce challenges for the materials engineering community for continuing the adoption of composites on future airplanes. As market and manufacturing challenges arise, new materials and process innovations for composites provide solutions for greater adoption of composites in the industry. It is an exciting time for the aerospace and composites industries as we move forward to tackle these new challenges.