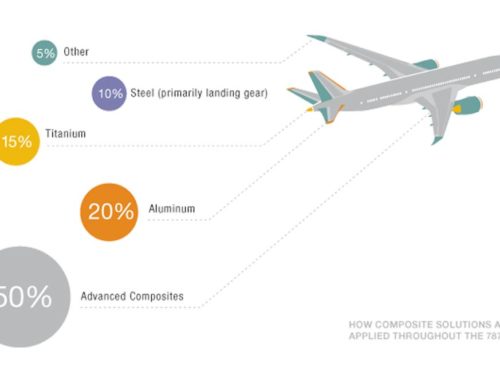

Advances in structural materials have been largely responsible for the major performance improvements in current Air Force (AF) systems and will be enabling to any significant performance gains in current and future systems. Air superiority can only be achieved by maximizing performance. Maximizing performance requires advanced materials such as advanced composites. Staying ahead of the threat environment leads to a need for major improvements in key performance metrics such as maneuverability and survivability, which, in turn, has led designers to turn to major increases in advanced composite usage. These materials allow unique combinations of designs, shapes, and weight savings that other materials cannot provide. The lightweight fighter – the F-16 – had limited usage (limited to the empennage) of advanced composites, about 3% of the structural weight, fairly modest by today’s numbers. The next generation of aircraft – the B-2 and the F-22 – saw major increases in composite usage from about 3% to 25-30% of the structural weight (Air University Report), The B-2’s use of advanced composites represented the first major usage increase in advanced composites by an AF system. Major gains in a key performance driver – survivability – have been achieved due to the combination of improved designs and advanced materials. New materials such as advanced composites have allowed missions to be performed with minimum detection and loss of aircraft and personnel. Similarly, the increase in performance from the F-16 to the F-22 was enabled by the increased use of advanced composites. Higher speeds resulted in the first wide scale use of a higher temperature matrix material – bismaleimides (BMIs). Major improvements in automation resulted in the use of tape placement in the horizontal stabilizer pivot shafts and resin transfer molding in numerous other parts. The desire to improve the damage tolerance of doors led to the first use of thermoplastic composites on a production AF aircraft. The F-22 was truly an advanced technology fighter.

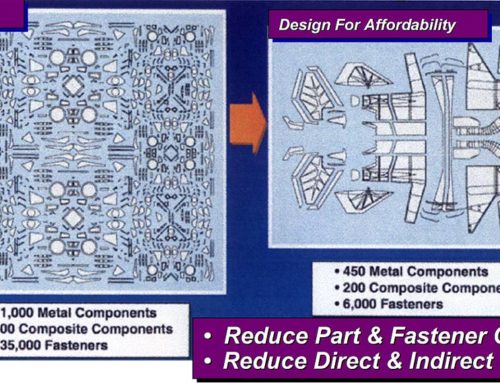

The AF has been very successful at developing and applying advanced materials in an extremely complex environment of new materials, materials systems, manufacturing processes, and operational requirements. Although enhanced performance continues to be a high priority, improvements must be affordable. However, affordability should be assessed in terms of the life cycle cost of the system. Revolutionary materials and processes, which in some cases are more expensive than those currently in use, may have a favorable overall impact on a system’s life cycle cost (and may also provide performance advantages).